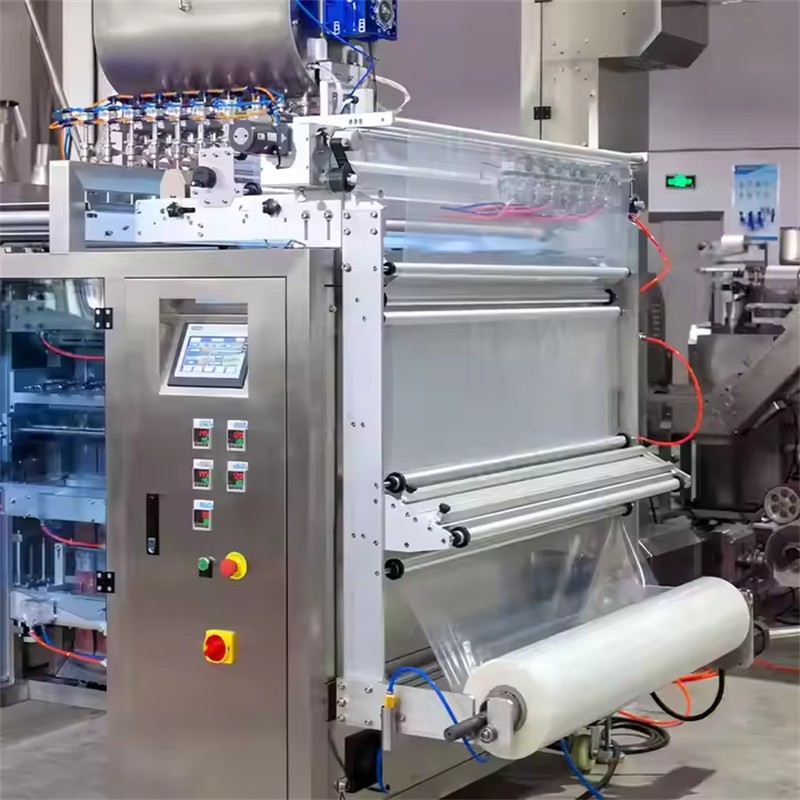

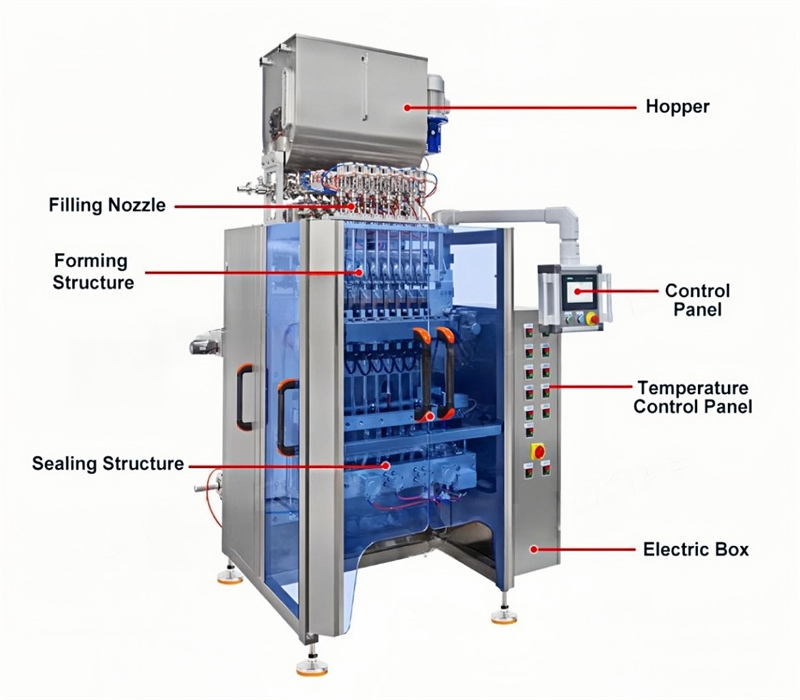

XLY-X1200 Liquid Multi Lane Packing Machine

Machine feature

1. Servo motor to control the sachet pushing, bag forming accuracy could be assured.

2. Eye marking checking sensor to guide the forming and sealing in the correction position.

3. The machine can be equipped with supporting machines like date coding machine.

4. Auxiliary equipment available such as feeding machine, date coding machine, finished product

conveyor and insulation mixing barrel.

5. Adopt brand components and PLC to ensure machine working synchronous.

6. All connect with product parts is made of stainless steel 304, to meet with GMP and CE standard.

7. All the works of bag making,measuring,filling,sealing,cutting and counting can be done automatically,

at the same time,it can also according to the demand of customers printing batch number and other

functions.

8. Auxiliary equipment:Heating, heat preservation mechanism, diaphragm pump, coding machine,

dust-collect, etc.

9. Pneumatic system for vertical and horizontal sealing.

Machine parameters

Type

XLY-X1200

Track Number

4-10 track

Capacity

Max.40 cycle/min

Sachet size

Width 35-90mm,Length 45-120mm can be customized

Film width & thickness

Max 720mm can be customized,0.07-0.1mm

Filling Method

Piston pump; Peristaltic pump

Power supply

220V、50Hz

Airconsumption

0.5-0.8m3/min

Equipment material

304 stainless steel

Application

This shaped bag sachet packing machine, could be used to pack liquid material,paste products in

daily chemical, food, health care and pharmaceutical industries, sticky product such as cosmetic,

cream,syrup, honey,drinks, chemical products and so on.

INQUIRY