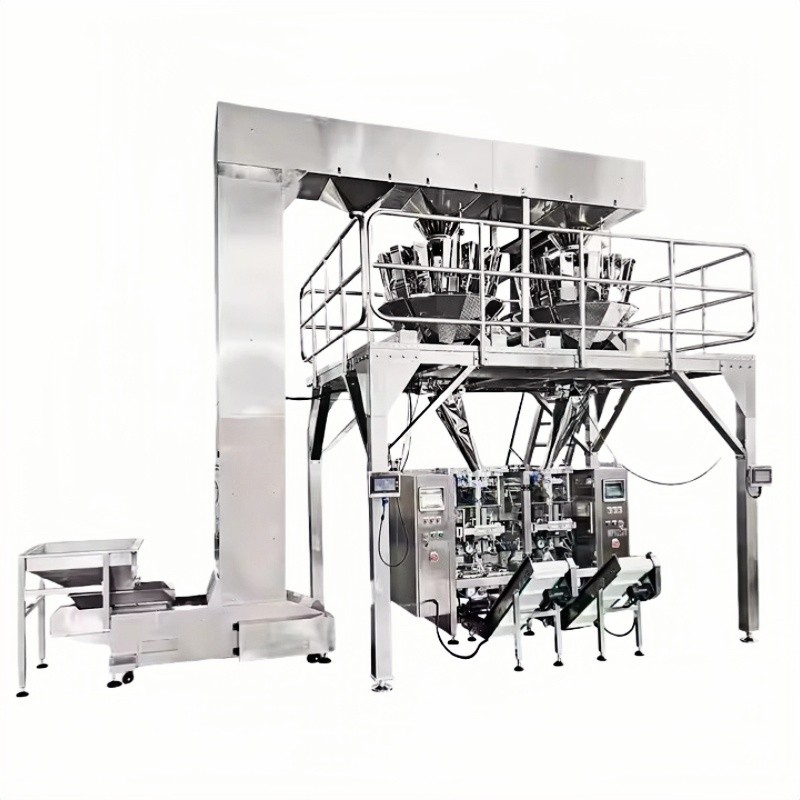

XLY-845 Automatic Weighing Packing Machine Fruit Packaging Machine

Machine parameters

Model

XLY-845

Bag size

(L)80-300mm

(W)80-200mm

Film width

Max.420mm

Film thickness

0.05-0.10mm

Packing range

10gs-1000gs/bag

Packing speed

40-180 bags/min

Air consumption

0.65Mpa, 0.8m³/min

Power supply

220V/380V 50-60Hz

Power

7KW

Dimension

L3550 x W3350 x H3450mm

Weight

3050kgs

Packing material

All laminated film such as PET/PE, PET/AL/PE, Nylon/PE, etc.; PE (confirm when order)

Main Features

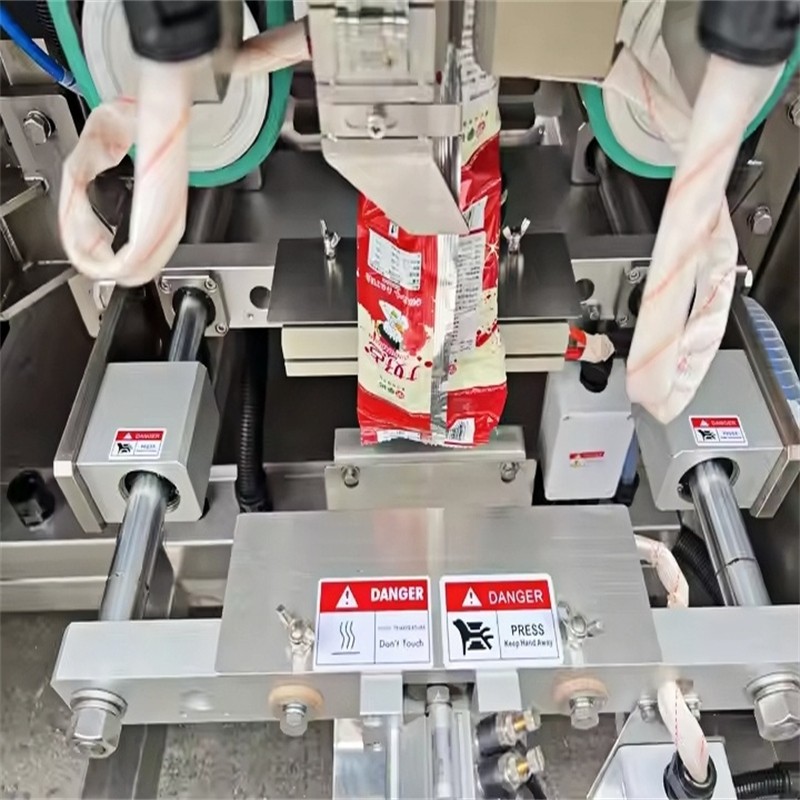

1.Equipped with safety protection,comply with firm's safety management requires.

2. PLC and HMI controller, easy to operate and maintain.

3.Servo film pulling system,photocell accuracy cutting position.

4. Touch screen can store the technical parameters of various kinds of products.No need to reset

while products changing.

5. Separate circuit boxes for power control and pneumatic control, low noise, good tightness and

more stable.

6. Automatically completed products feeding,forming, filling, gas flushing (exhausting), sealing,cutting,

date printing and counting.

7. Have error indicating system, helping handle the trouble immediately.

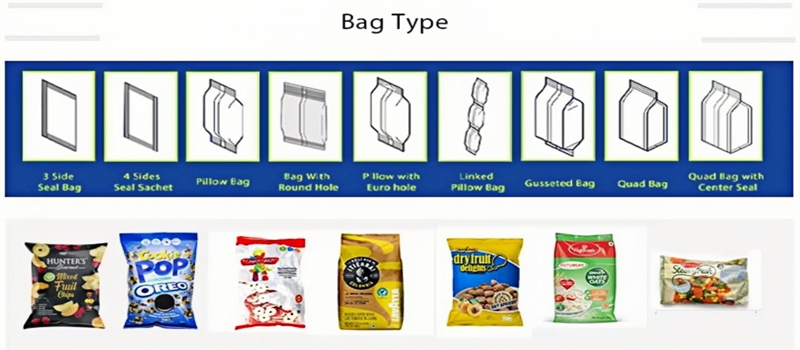

8. The device of gusseted bag, linked bag, punching device etc for optional.

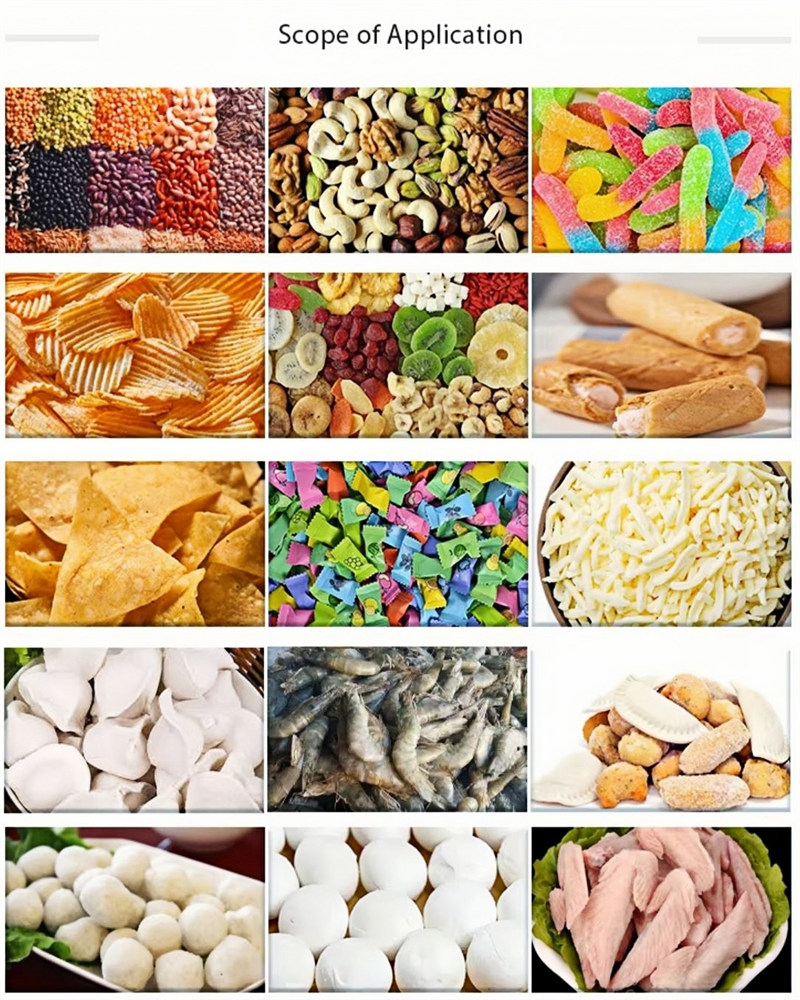

Application

It's suitable to pack high accuracy and easy fragile material,such as puffy food, crispy rice, jelly, candy,

pistachio, apple slices, dumpling, chocolate, pet food, small hardwares, toys, puffs, etc.