XLY-1000 Stainless Steel Beverage Mixing Tanks With Agitator and Blending

Product description

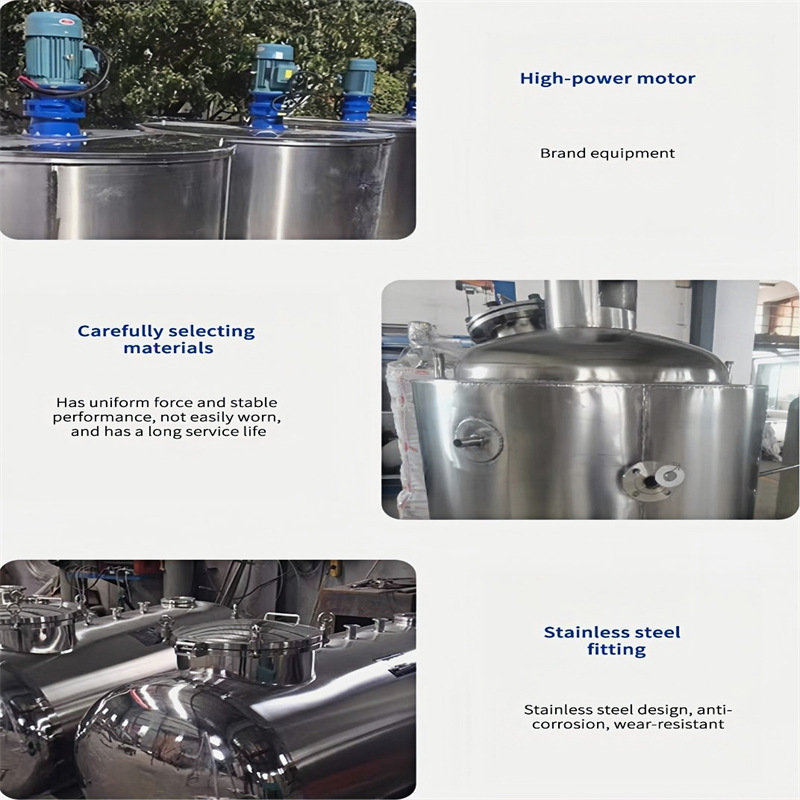

Mixing tank is mainly used for mixing, mixing,blending and homogenizing materials. Stainless steel

mixing tank effectively shortens the mixing time, saves labor and speeds up production. It is the main

equipment for modern industrial production.

Product parameters

| Model | Effective volume(L) | Dimension of tank(D*H)(mm) | Total Height(mm) | Motor power(kw) |

| XLY-1000 | 1000 | 800x900 | 2100 | 0.75 |

| XLY-2000 | 2000 | 1200x1500 | 2500 | 1.5 |

| XLY-3000 | 3000 | 1600x1500 | 2600 | 2.2 |

| XLY-4000 | 4000 | 1600x1850 | 2900 | 2.2 |

| XLY-5000 | 5000 | 1800x2000 | 3150 | 3 |

| XLY-6000 | 6000 | 1800x2400 | 3600 | 3 |

| XLY-8000 | 8000 | 2000x2400 | 3700 | 4 |

| XLY-10000 | 10000 | 2100x3000 | 4300 | 5.5 |

Feature

1. Reactor is widely used in pharmaceutical, fine chemical, biological engineering and dairy industries.

2. Whole-enclosed design ensures that materials are always mixed and ferment at non-pollution state.

3. tank is equipped with devices like air respirator, cleaning ball, sanitation manhole, viewing mirror and

viewing light.

4. The fermentation process of pharmacy, fine chemical engineering and biological products is aseptic

and untainted. tank adopts aseptic system which helps avoid microorganism pollution in the air and

greatly extends quality warranty period and purity of the products.

5. This tank is especially designed and installed with aseptic respirator or aseptic normal pressure

fermentation system.

6. The parts contacted with material are all made using SUS304 or SUS316.

7. External surface is matte finished.

Application